About Our Company

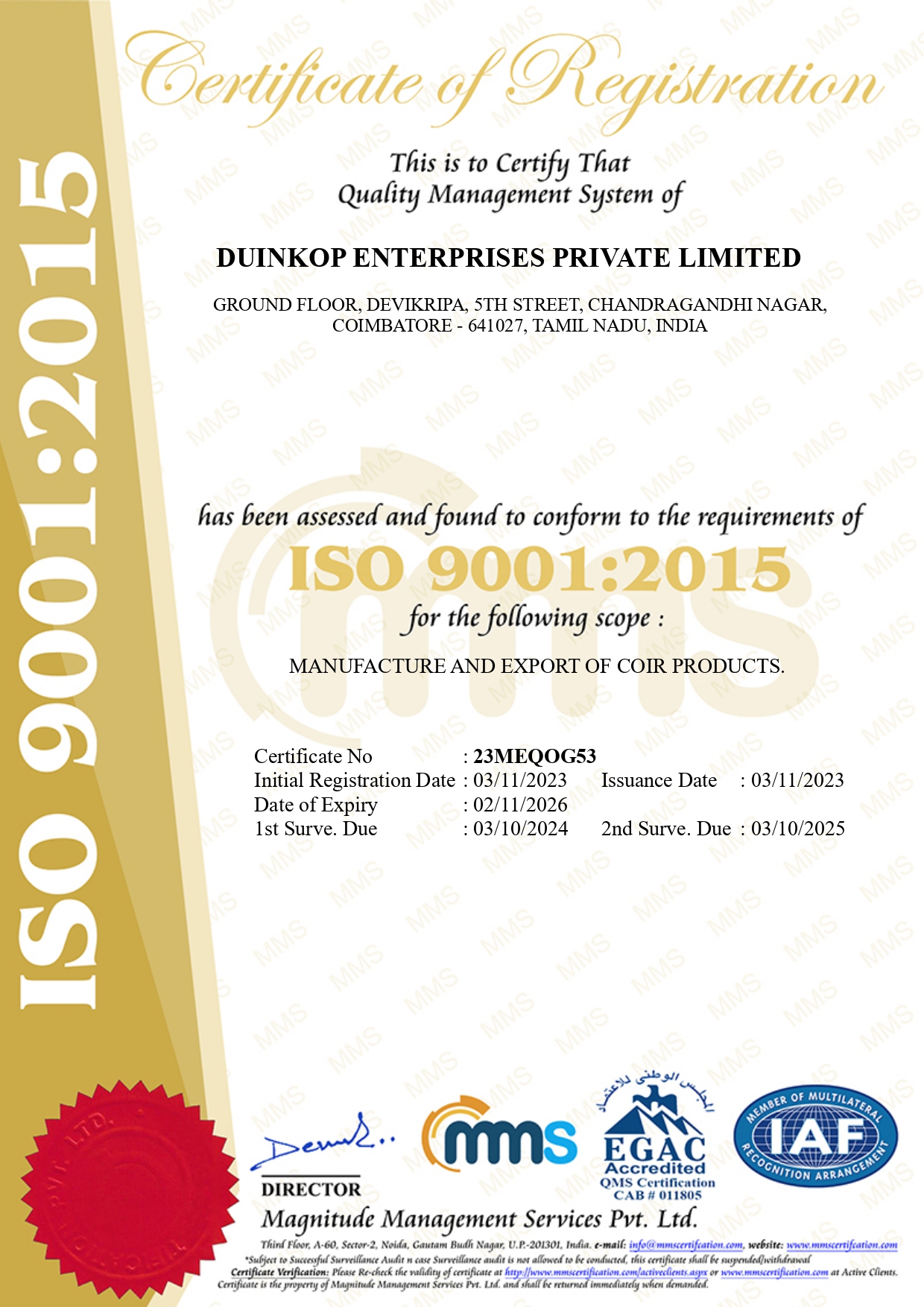

DUINKOP ENTERPRISES

Manufacturer & Exporter of Cocopeat, Coir & Agriculture Products

Duinkop Enterprises (P) Ltd., located in the Coimbatore district of South India, was established in 1996. Specializing in the manufacturing and export of premium coco peat products, our company is strategically situated in the heart of coconut county amidst vast plantations spanning thousands of acres. Our advantageous location, coupled with an abundance of high-quality raw materials and favorable climatic conditions, enables us to excel in manufacturing operations.

Duinkop has emerged as a leading processor of top-tier coco peat material, having invested significantly in skilled personnel, cutting-edge machinery, and state-of-the-art sustainability practices. Our production facility is manned by a team of seasoned experts boasting extensive knowledge, each contributing over 20 years of dedicated service to the company since its inception.